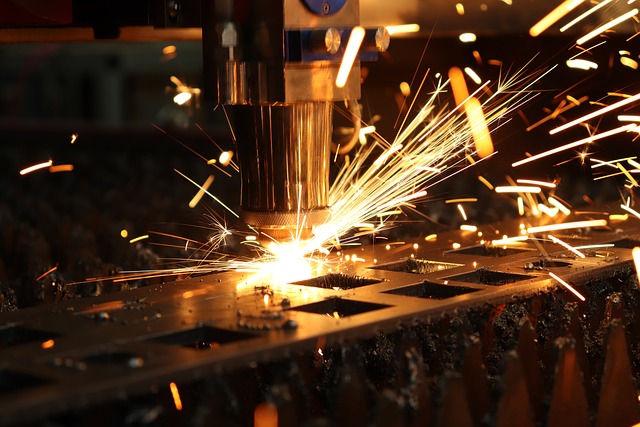

CNC (Computer Numerical Control) routers are now the top choice for precision manufacturing and automated woodworking. They offer many benefits over traditional hand tools. These machines have changed how we design, make, and finish products, making them more accurate, efficient, and cost-effective.

CNC routers are known for their ability to produce consistent, precise results. Unlike manual tools, which depend on human skill, CNC routers use computer control. This means every cut, shape, and detail is made with perfect accuracy, every time.

Also, CNC routers reduce the chance of human mistakes, making the manufacturing process more consistent and reliable. This leads to big savings in time and money for businesses. It’s true for many industries, from woodworking and furniture making to aerospace and cars.

What Makes CNC Routers Superior to Traditional Tools?

CNC (Computer Numerical Control) routers have clear advantages over traditional woodworking tools. They offer unmatched cnc accuracy and seamless automated manufacturing integration. CNC routers excel in precision, consistency, and efficiency, far surpassing manual methods.

Precision and Repeatability in CNC Routers

CNC routers stand out for their unmatched precision and repeatability. They use advanced computer systems to make precise cuts and shapes. This cnc accuracy is often within a millimeter, far beyond what hand tools can achieve. This ensures consistent quality in every production run.

CNC Routers and Automation: Less Human Error, More Consistency

CNC routers automate the manufacturing process, reducing human error. They follow pre-programmed instructions consistently, unlike manual methods. This makes CNC machines a reliable choice for automated manufacturing.

Efficiency and Time Savings in CNC Routing

CNC routing is incredibly fast and efficient. These machines can make complex cuts much quicker than manual methods. This leads to higher production output and shorter lead times. CNC routers are key to modern manufacturing’s efficiency and time savings.

Key Benefits of CNC Routers Over Traditional Hand Tools

CNC routers have changed the game in woodworking and manufacturing. They offer many benefits that make production faster and more creative. Unlike old hand tools, these machines make work easier and more precise.

Complex Shapes and Intricate Designs Made Easier

CNC routers are great at making complex shapes and designs. They can carve out detailed patterns and 3D shapes with high accuracy. This lets manufacturers create intricate CNC designs with ease and consistency.

Reduced Labor Costs with CNC Routers

CNC routers save a lot of money compared to hand tools. They automate tasks, reducing the need for manual labor. This leads to big cost-effective manufacturing savings for companies.

Speed and Efficiency in Mass Production

In mass production, CNC routers are unbeatable. They work fast and accurately, making high-quality products quickly. This makes them key for rapid prototyping and big projects.

The benefits of CNC routers over hand tools are clear. They make creating complex designs easy and save money. These machines have changed how businesses make things in woodworking and manufacturing.

Comparing CNC Routers to Traditional Woodworking Tools

The woodworking world is changing fast. Now, people talk more about CNC routers versus old-school tools. CNC routers are better in many ways, like precision, durability, and how easy they are to use.

How CNC Routers Offer Higher Precision than Traditional Methods

CNC routers are all about precision. They use computers to make cuts perfectly, without any mistakes. This means better designs, consistent quality, and less waste in woodworking projects.

Durability and Tool Life: CNC vs Traditional Tools

CNC routers last longer than old tools. They’re built strong and work well for a long time. This means less money spent on fixing tools and more work done, making CNC routers a smart choice for woodworking.

The Learning Curve: Operating a CNC Router vs Traditional Tools

Old tools might be easier to start with, but CNC routers are worth learning. With some training, you can use CNC routers to do more and work faster. Learning CNC pays off with better results and more design options.

| Feature | CNC Routers | Traditional Woodworking Tools |

|---|---|---|

| Precision | Highly precise, computer-controlled algorithms ensure accuracy | Dependent on the skill and experience of the operator, potential for human error |

| Tool Longevity | Robust construction and specialized components lead to extended tool life | Shorter tool lifespan, requiring more frequent replacement and maintenance |

| Learning Curve | Requires cnc operation training, but offers long-term productivity gains | Shorter initial learning curve, but limited in advanced capabilities |

Common Applications for CNC Routers

CNC routers are key tools in many industries. They are used in woodworking, furniture making, aerospace, and more. Their precision and versatility make them essential for many tasks.

Woodworking and Furniture Manufacturing

In woodworking and furniture making, CNC routers have changed the game. They can make detailed designs and shapes with great precision. This makes them vital in both custom furniture shops and big factories.

They are great at cnc furniture production. This means they help make high-quality furniture faster than old methods.

Aerospace and Automotive Applications

CNC routers are also important in aerospace and automotive. These fields need precise engineering and parts. CNC routers can handle these tasks well.

They help make complex parts for planes and cars. This is a big help in aerospace manufacturing.

Custom Design and Prototyping

CNC routers are also great for custom prototyping. They let designers and engineers make their ideas real with high accuracy. This makes it easy to test and improve new designs quickly.

| Application | Key Benefits of CNC Routers |

|---|---|

| Woodworking and Furniture Manufacturing |

|

| Aerospace and Automotive |

|

| Custom Design and Prototyping |

|

Why Shixinproto Should Be Your Go-To for CNC Router Services

Shixinproto is the top choice for businesses looking for custom manufacturing solutions. They have a team of expert CNC technicians and the latest equipment. This means they deliver top-notch precision, efficiency, and quality in every project.

Shixinproto is all about excellence. They pay close attention to every detail and focus on making customers happy. Whether you’re in woodworking, aerospace, or automotive, they can make your ideas come to life. They handle complex shapes, intricate designs, and high-volume production with ease.

Working with Shixinproto means you get great teamwork, quick communication, and a focus on you. They have a strong track record of successful projects. This has earned them the trust of many businesses across different industries. They are the go-to for professional CNC services and custom manufacturing solutions.