The automotive world is always looking for ways to make cars lighter and more powerful. High pressure die cast (HPDC) magnesium is a key player in this search. It has special properties that make it perfect for improving car performance and saving fuel.

The need for cars that are better for the environment and more efficient is growing. Lightweight automotive solutions like HPDC magnesium are at the forefront. They promise to change how cars are made. But what makes magnesium so special, and how will it change the car industry?

What is High Pressure Die Casting?

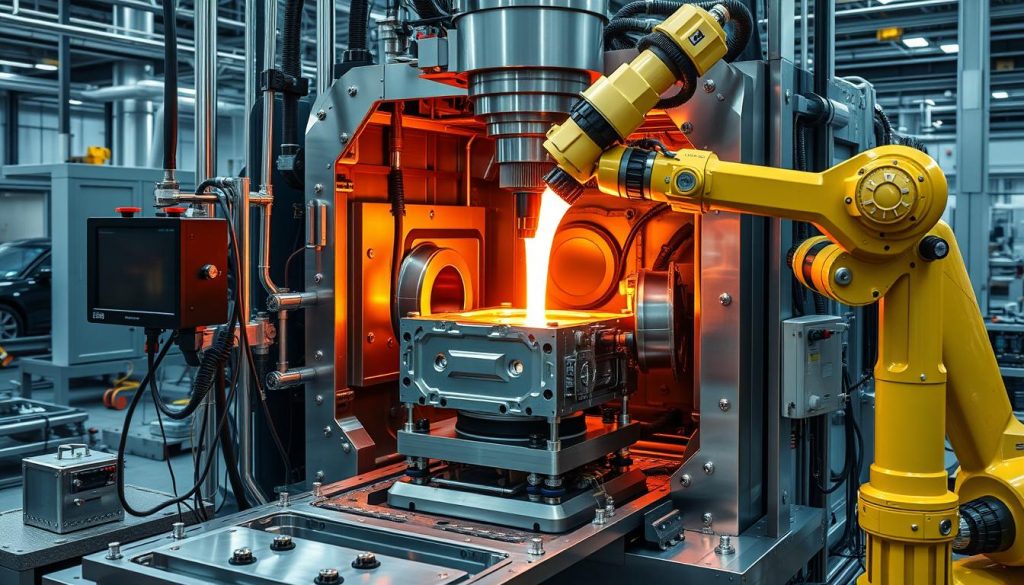

High Pressure Die Casting (HPDC) is a key method in making car parts. It uses molten metal, like magnesium or aluminum, to create detailed parts. This method is fast and precise, making it popular in the car industry.

Overview of the HPDC Process

The HPDC process has several important steps:

- Melting: The metal, like magnesium or aluminum, is heated until it’s liquid.

- Injection: The hot metal is pushed into a mold at high pressure, over 1,000 psi.

- Solidification: The metal cools and hardens in the mold, taking the part’s shape.

- Ejection: Once solid, the part is taken out of the mold, ready for use.

Advantages of Using Magnesium in HPDC

Magnesium is a strong, yet light metal, great for HPDC in cars:

- Excellent Fluidity: Magnesium flows well, making it perfect for complex parts.

- Rapid Solidification: It cools fast, speeding up production.

- Lightweight Properties: Its low density helps make cars lighter, saving fuel.

Magnesium’s special qualities make it ideal for HPDC in cars. It’s light, strong, and cost-effective.

Benefits of Magnesium in Automotive Manufacturing

Magnesium is changing the game in the auto industry. It offers many benefits that improve performance and help the environment. Its light weight boosts fuel efficiency, and its strength and resistance to corrosion make it a top choice for car parts.

Lightweight Properties for Fuel Efficiency

Magnesium is very light, making it great for cars. It’s about one-third lighter than aluminum and one-quarter lighter than steel. This lightness helps cars use less fuel and produce fewer emissions. It’s good for the planet and saves money on gas.

High Strength-to-Weight Ratio

Magnesium is strong for its weight. It’s perfect for making car parts that are both light and strong. This lets car makers create vehicles that are fuel-efficient and safe, without losing performance.

Corrosion Resistance for Longevity

Magnesium parts resist corrosion well. They can handle salt, chemicals, and weather, making cars last longer. This means less money spent on repairs and a longer car life, making it a smart choice for car owners.

Using magnesium in cars makes them more efficient and durable. It also helps the environment. As car technology advances, magnesium will be key in making cars better for the planet and more powerful.

Applications of Magnesium Die Casting in Automotive

Magnesium is a versatile material for many car parts. It’s used in structural parts, safety features, and even for looks. High pressure die cast magnesium is changing the car industry.

Structural Components: Engine Blocks and Transmission Housings

Magnesium is strong yet light, perfect for engine blocks and transmission housings. Using magnesium instead of aluminum or steel makes cars lighter. This leads to better fuel use and performance.

Safety Components: Instrument Panels and Crash Boxes

Magnesium absorbs energy well, making it great for safety parts like instrument panels and crash boxes. In crashes, these lightweight safety features help keep people safe by spreading out the force of impact.

Decorative Components: Wheels and Trim

Magnesium is also good for making car parts look nice. Engine block materials like magnesium can be shaped into fancy designs. This makes stylish wheels, trim, and other parts that make cars look better.

| Magnesium Application | Advantages |

|---|---|

| Engine Blocks and Transmission Housings | Reduced weight, improved fuel efficiency, enhanced performance |

| Instrument Panels and Crash Boxes | Energy absorption, improved safety in collisions |

| Wheels and Trim | Intricate designs, enhanced aesthetic appeal |

Using magnesium, car makers can make many new and better parts. This meets the changing needs of the car industry.

Challenges in Using High Pressure Die Cast Magnesium

Magnesium die casting has many benefits for cars, like being light and resistant to corrosion. But, it also has some big challenges. These include higher material costs than usual materials and issues with porosity and defects in the casting.

Material Costs and Availability

One big challenge is the cost of magnesium. It’s pricier than aluminum or steel, which are common in cars. Also, finding magnesium can be hard because it’s not made everywhere. The world’s supply is small, and it’s mainly made in a few places.

Addressing Porosity and Defects

Magnesium casting also faces issues with porosity and other casting defects. This is because magnesium is light and reacts easily. To fix this, makers need to control the casting process well. This means watching the temperature, pressure, and mold design closely.

Companies must use new casting methods and strict quality checks. This way, they can overcome magnesium’s challenges. This will help them use this material fully in car making.

“Proper material selection and process control are critical in overcoming the challenges of using high pressure die cast magnesium in automotive manufacturing.”

Future Trends in Magnesium Die Casting

The automotive world is changing fast, and magnesium die casting is at the forefront. It’s becoming key for making electric vehicles (EVs) lighter. This is because magnesium is very light, which helps EVs go further and use less energy.

Integration with Electric Vehicle Manufacturing

As more people want electric cars, car makers are looking at magnesium die casting. It’s strong yet light, perfect for EV parts like battery boxes and motor cases. Using magnesium can make EVs lighter, faster, and better to drive.

Advances in Magnesium Alloy Technologies

New magnesium alloys are being made to make cars even better. Scientists are working on stronger, more durable magnesium. This means cars can be lighter, safer, and more efficient. It’s a big step forward for magnesium in the car industry.