In today’s fast world, picking the right sheet metal is key. It affects everything from car parts to big machines. The metal you choose can change how well your products work, last, and cost. But what really matters when picking the best metal for your needs? Discover the secrets to material selection and how it can change your making processes

Common Sheet Metal Materials

There are many sheet metal materials to choose from for fabrication. Each has its own special properties and uses. Let’s look at three common ones: aluminum, steel, and copper.

Aluminum: Lightweight and Corrosion Resistant

Aluminum is a favorite for sheet metal because it’s light and doesn’t rust easily. It’s perfect for places where you need to save weight, like cars and planes. It also works well outside and in the water because it doesn’t corrode.

Steel: Strong and Durable

Steel is a top pick for sheet metal because it’s strong and lasts a long time. It’s used in big machines, buildings, and tools that need to carry heavy loads. Its strength and affordability make it great for many uses.

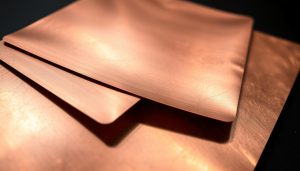

Copper: High Conductivity for Specialized Applications

Copper is great for things that need to conduct heat or electricity well. It’s often used in heat exchangers, electrical parts, and other special products. This makes it a key material for certain jobs.

| Sheet Metal Type | Key Properties | Common Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive, aerospace, outdoor equipment |

| Steel | Strong, durable | Industrial machinery, construction, equipment |

| Copper | High conductivity | Heat exchangers, electrical components, specialized products |

Knowing what each sheet metal type can do is key when picking the right one for your project. Think about strength, how it holds up to rust, and how well it conducts. This way, your project will meet its goals and be cost-effective.

Factors to Consider When Choosing Materials

Choosing the right sheet metal material is key for a project’s success. It affects the product’s performance, cost, and how green it is. Important things to think about include the material’s strength, how it bends, its resistance to corrosion, and its cost.

Strength and Ductility

The strength and flexibility of sheet metal are crucial. Strong materials like steel can handle heavy loads. On the other hand, materials like aluminum are flexible and can be shaped easily.

Knowing what your product needs in terms of strength and flexibility is important. This helps pick the best material for your project.

Corrosion Resistance and Environmental Compatibility

It’s important for materials to resist corrosion and be good for the environment. Products exposed to harsh conditions or chemicals need materials that can handle it. Stainless steel and copper are great at resisting corrosion.

Aluminum can also be treated to protect it from corrosion. Think about where your product will be used. This helps choose a material that will last and stay strong.

Cost Efficiency and Availability

Cost and availability are also big factors. High-performance materials might be the best choice technically, but they can be expensive. Their availability can also be a problem.

It’s important to find a balance between what the material can do, its cost, and how easy it is to get. This helps manufacturers choose the best and most affordable option for their needs.

| Material Selection Criteria | Importance | Considerations |

|---|---|---|

| Strength and Ductility | High | Ability to withstand loads, structural integrity, and formability |

| Corrosion Resistance and Environmental Compatibility | High | Resistance to weathering, chemicals, and harsh environments |

| Cost Efficiency and Availability | Medium | Material cost, supply chain considerations, and manufacturing feasibility |

By carefully looking at these factors, manufacturers can choose the best sheet metal materials. This ensures their products work well, are cost-effective, and are good for the environment.

Applications of Sheet Metal Materials

Sheet metal materials are used in many industries. They are versatile and adaptable. These materials are key in making the products we use every day.

Automotive and Aerospace Components

In the car industry, sheet metal is used for body panels and more. Aluminum and steel alloys are chosen for their strength and light weight. This helps cars use less fuel and be safer.

In aerospace, sheet metal is used for aircraft parts. It makes the planes light but strong.

Industrial Machinery and Tools

Sheet metal is vital for making industrial machines. Steel sheets are used for heavy equipment. Metals like stainless steel are used for durability and to resist corrosion.

Consumer Products and Electronics

Sheet metal is also used in consumer products and electronics. It’s strong and looks good. Copper sheet metal is great for electrical uses because it conducts electricity well.

| Industry | Sheet Metal Applications |

|---|---|

| Automotive | Body panels, hoods, doors, structural components |

| Aerospace | Aircraft fuselages, wings, critical components |

| Industrial Machinery | Heavy-duty equipment, construction machinery, agricultural implements |

| Consumer Products | Household appliances, office furniture, electronic enclosures |

Sheet metal is essential in many industries. It’s used in cars, planes, machines, and electronics. As technology grows, so does the use of sheet metal.

Shixinproto’s Expertise in Sheet Metal Fabrication

Shixinproto is known for top-notch sheet metal fabrication services. They have years of experience and know a lot about different materials. They provide custom solutions for all kinds of manufacturing projects.

Comprehensive Material Selection and Fabrication Services

Shixinproto’s team helps clients pick the right materials for their projects. They work with everything from strong steel to light aluminum and copper that resists corrosion. This means they can make high-quality parts that meet or exceed your expectations.

Why Shixinproto is the Best Partner for Your Project

Shixinproto has a strong history of working well with businesses. They are known for their quality, focus on details, and creative approach to metal work. Choosing them ensures your project will be a success.