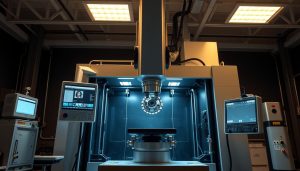

In today’s fast world, CNC (Computer Numerical Control) machine tools are key to making things. But, what makes these machines so important in making things? We’ll explore the world of CNC machine tools. We’ll see what makes them change how we make products.

CNC machine tools are at the heart of advanced making. They bring precision, efficiency, and customization to new levels. Check out the detailed guide to see how these machines are changing making in many fields, from aerospace to cars.

What Are CNC Machine Tools?

In today’s manufacturing world, CNC machine tools are key. They are computer-controlled machines that do many tasks with great precision and speed. This has changed how manufacturers work.

Definition and Purpose

CNC stands for Computer Numerical Control. It lets machines work by following computer instructions. These tools can shape, cut, and finish many materials like metals, plastics, wood, and composites.

Importance in Modern Manufacturing

The use of CNC machine tools has changed the game in manufacturing. They bring many benefits, including:

- Increased precision and consistency in product quality

- More productivity and efficiency, cutting down on time and waste

- The ability to make complex shapes and designs that are hard or impossible to do by hand

- Smooth integration with automated manufacturing, controlling the whole production line with computer numerical control

Using CNC machine tools helps manufacturers stay ahead. They meet market demands and stay competitive globally.

“The integration of CNC technology has transformed the manufacturing industry, empowering companies to achieve new levels of precision, efficiency, and innovation.”

Types of CNC Machine Tools

CNC (Computer Numerical Control) machine tools come in many types, each for different tasks. You can find cutting tools, turning tools, and specialty tools. Knowing what each type does helps you pick the right one for your needs.

Cutting Tools: End Mills, Drills, and Taps

CNC cutting tools are key for shaping, drilling, and threading. End mills help make grooves, contours, and pockets. Drills create holes, and taps cut internal threads for fasteners.

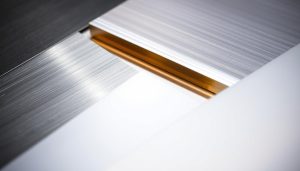

Turning Tools: Inserts and Boring Bars

CNC turning tools work on rotating workpieces, like turning and threading. Inserts are easy to swap out, making them cost-effective. Boring bars enlarge or refine holes, ensuring precise sizes.

Specialty Tools: Thread Mills and Engraving Tools

CNC shops also use specialty tools for unique tasks. Thread mills make external threads, and engraving tools add designs or marks.

Knowing about CNC tools and their uses is key for better manufacturing. The right tools can make your CNC work more productive and of higher quality.

Key Factors to Consider When Selecting CNC Tools

Choosing the right CNC tools is key for top performance and efficiency. You need to think about material compatibility, tool geometry, and feed rate optimization. Each factor is important for the success of your projects.

Material Compatibility

Material compatibility is a top priority when picking CNC tools. The tool and workpiece materials must match well. The wrong tool can cause wear, lower efficiency, and harm the workpiece. Knowing the material properties helps make the best CNC tool selection.

Tool Geometry and Coatings

The shape and coatings of CNC tools greatly affect their performance. The tool’s design, like the number of flutes and helix angle, influences chip formation and surface finish. Special coatings can also boost tool life and reduce friction, leading to better machining.

Speed and Feed Rate Optimization

- Choosing the right spindle speed and feed rate is vital for good results.

- Consider the tool, workpiece, and cutting conditions to optimize these settings.

- Optimizing speed and feed rates can improve finish, tool life, and productivity, making it crucial for CNC tool selection.

| Criteria | Recommended Range |

|---|---|

| Spindle Speed | 3,000 – 12,000 RPM |

| Feed Rate | 10 – 100 inches per minute |

Understanding these key factors helps manufacturers choose the best CNC tools for their needs. This leads to better productivity, quality, and cost-effectiveness.

“Selecting the right CNC tools is crucial for achieving optimal performance and precision in manufacturing processes.”

Maintaining and Extending the Life of CNC Tools

Keeping your CNC tools in good shape is key for a smooth and efficient factory. By storing and handling them right, and checking them often, you can make them last longer. This helps your factory stay productive and saves money.

Proper Storage and Handling

Storing and handling CNC tools correctly makes them last longer. Keep them in a clean, dry place, away from moisture and dust. Use tool cabinets to protect them from damage and wear.

Regular Tool Inspections and Replacements

Checking your CNC tools regularly is vital. Look for signs of wear or damage. Replace them when needed to keep your factory running smoothly. This way, you avoid downtime and keep your tools working well.