In today’s fast-paced world of product development, picking the right CNC machining prototype service is crucial. But what are the key factors to consider when choosing a partner for your CNC needs? Are you sure your current CNC service provider meets your quality and efficiency standards?

Finding the right CNC machining prototype service can be tough. There are many options and varying levels of expertise. However, the right choice can greatly affect your product’s quality, timeline, and cost. The right CNC service provider can ensure your product’s success or lead to costly delays.

Why Selecting the Right CNC Prototype Service Matters

Choosing the right CNC prototype service is crucial for your product’s quality and development speed. Working with a trusted CNC service provider opens up many benefits. These can help your business stand out.

The Impact on Product Quality and Development Timelines

CNC machining is known for making high-quality prototypes with great precision. A skilled CNC service uses the latest tech and expertise. This helps refine your designs, cut down on mistakes, and ensure top-notch product quality.

This leads to faster development timelines. You can get your products to market quicker. This keeps you ahead of the competition.

How a Reliable Partner Reduces Costs and Errors

Working with the right CNC service can also save you money. A reliable partner will find the most cost-effective ways to meet your project needs. This helps reduce costs without sacrificing quality.

They also focus on details to minimize errors in the prototyping process. This saves you time and resources that would be spent on fixing mistakes.

“Choosing the right CNC prototype service can be a game-changer for your business, streamlining your product development process and ensuring you deliver high-quality products to your customers.”

By picking the right CNC prototype service, you open up many possibilities. It boosts your product quality, speeds up development, and cuts costs. The benefits of a reliable CNC partner are truly priceless.

Key Factors to Consider When Choosing a CNC Service

Choosing a CNC machining service requires careful thought. You need to look at quality, cost, and how fast it will be done. By focusing on these areas, you can find a reliable and skilled partner for your project.

Expertise and Industry Experience

The CNC service provider’s experience is very important. Choose a company that knows your industry well. They will understand what you need and do it right, saving time and reducing mistakes.

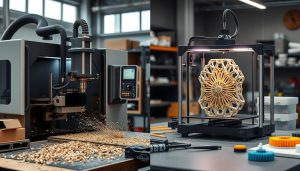

Equipment Capabilities and Advanced Technology

The technology and equipment used by the CNC service matter a lot. Make sure they have the latest machines and tools. This ensures your project is done quickly and accurately.

Material Availability and Specialization

It’s also important to see what materials the CNC service can work with. They should be able to handle a variety of materials, including special ones. This means they can make parts that meet your exact needs.

| Key Considerations | Why It Matters |

|---|---|

| Industry Experience | Demonstrates a deeper understanding of your industry’s unique requirements and best practices, leading to more efficient project execution and higher-quality results. |

| Advanced Technology | Ensures the CNC service provider can handle complex specifications and requirements using the most efficient and accurate methods, resulting in faster turnaround times and better part quality. |

| Material Specialization | Allows the CNC service provider to work with a wide range of materials, including specialized options, to meet the unique needs of your product design and performance requirements. |

By carefully evaluating these key factors, you can identify a CNC service provider that aligns with your project’s specific needs and ensures a successful outcome.

Evaluating CNC Service Providers

Choosing the right CNC prototype service is key. You want a reliable and reputable partner. Look at certifications, customer feedback, and cost comparisons to make the best choice.

Reviewing Certifications and Quality Standards

Check if the CNC service has industry-recognized certifications like ISO 9001 or AS9100. These show they follow quality management and manufacturing best practices.

Assessing Customer Reviews and Case Studies

Customer feedback and case studies offer insights into a CNC service’s performance. Look at online reviews and client references to see their track record and quality.

Comparing Costs and Lead Times

Cost is important, but don’t forget about lead times. Compare prices and any extra fees. Also, check if they can meet your project timeline quickly.

| CNC Service Provider | Quality Certifications | Customer Reviews | Costs | Lead Times |

|---|---|---|---|---|

| Shixinproto | ISO 9001, AS9100 | 4.8/5 stars, 95% positive | $50 – $500 per part | 7-10 business days |

| Provider A | ISO 9001 | 4.2/5 stars, 88% positive | $75 – $600 per part | 10-15 business days |

| Provider B | None | 3.7/5 stars, 82% positive | $40 – $450 per part | 12-18 business days |

By carefully evaluating CNC service providers, you can find the best match. Look at quality, cost, and lead times to make a smart choice.

Questions to Ask Before Making Your Decision

Choosing a CNC machining prototype service requires asking the right questions. This ensures a smooth and successful project. Knowing about the provider’s expertise, how they communicate, and their revision process helps you make a good choice.

What is Their Experience with Similar Projects?

Find out if the CNC service provider has worked on projects like yours. Ask for examples and case studies. This shows their project experience and if they can meet your product’s needs.

How Do They Handle Revisions and Feedback?

Good communication and quick response to customer feedback are key. Ask how they handle design changes and feedback. Make sure they can meet your expectations and keep you satisfied with the final prototype.

| Key Considerations | Importance |

|---|---|

| Project Experience | Ensures the provider can deliver quality prototypes tailored to your needs |

| Revision Process | Allows for seamless incorporation of feedback and modifications |

| Communication | Facilitates transparency and collaboration throughout the project |

| Customer Feedback | Demonstrates the provider’s commitment to client satisfaction |

By asking these questions, you can find a CNC machining prototype service. They should have the technical skills and care for customers. This ensures a successful and collaborative project.

Shixinproto’s CNC Prototype Services

Shixinproto is a top name in CNC prototyping. They offer a wide range of services for modern manufacturers. Their focus on expertise, versatility, and customer satisfaction makes them a trusted partner for businesses.

Shixinproto’s team includes skilled engineers and technicians with lots of CNC machining experience. They use the latest equipment and technology. This means they can create precise prototypes from many materials, like aluminum, stainless steel, and advanced composites.

Shixinproto is all about quality. They follow strict industry standards and keep improving their processes. This ensures their prototypes meet or exceed customer expectations. They understand the need for quick prototyping in today’s fast business world. Shixinproto aims to give clients the speed and flexibility they need to stay competitive.