In the world of manufacturing and construction, rivets are key for joining materials. They make strong and durable connections. But, with so many rivet types, picking the right one can be tough. This guide will help you understand different rivets, their uses, and how to choose the best one for your project.

Want to find the perfect fastening solution for your needs? This article will take you through the world of rivets. We’ll look at each type’s unique features and uses. This will help you make smart choices for your projects.

What Are Rivets and How Do They Work?

Rivets are a key type of permanent fasteners used in many fields. These include automotive, aerospace, construction, and manufacturing. They are important for metal joining, making strong and lasting connections between materials.

Definition and Function of Rivets

Rivets are metal pieces with a head and a shaft. The shaft goes through holes in the materials to be joined. Then, the end of the shaft is shaped to create a second head, locking the materials together. This rivet mechanics makes a strong, permanent bond between the parts.

Common Uses of Rivets in Manufacturing

- Automotive industry: Rivets hold body panels, frame parts, and other structural parts of vehicles together.

- Aerospace industry: They are vital for joining parts of aircraft, like the fuselage and wings, ensuring safety and strength.

- Construction industry: Rivets are used to connect steel beams, trusses, and other structural parts in buildings and projects.

- Consumer goods and electronics: Rivets fasten parts in many products, from laptops and phones to outdoor gear and furniture.

Rivets are crucial permanent fasteners in metal joining and making various products. Their strength and durability make them a top choice for many industries.

| Industry | Application |

|---|---|

| Automotive | Body panels, frame components, structural elements |

| Aerospace | Aircraft fuselage, wings, structural components |

| Construction | Steel beams, trusses, structural elements |

| Consumer Goods and Electronics | Laptop and smartphone components, outdoor gear, furniture |

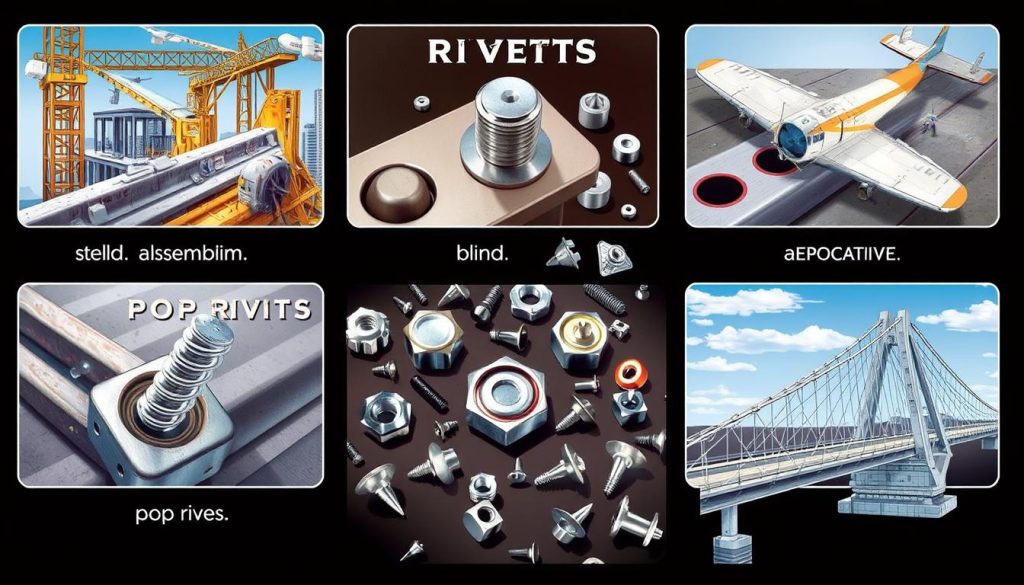

Different Types of Rivets

Rivets are a versatile and reliable fastening solution. They come in various types, each with its own strengths. Let’s explore solid, blind, tubular, and split rivets.

Solid Rivets: Strength and Durability

Solid rivets are top-notch for where strength matters most. Made from a single metal piece, they’re hammered or gunned into place. They’re strong, making them a favorite in car, plane, and heavy-duty making.

Blind Rivets: Easy Installation

Blind rivets, or “pop” rivets, are great for tight spots. You can install them from one side, perfect for small spaces. They’re used in many fields, from tech to building, because they’re easy to use.

Tubular Rivets: Lightweight and Cost-Effective

Tubular rivets are light and affordable. Their hollow design balances strength and weight. They’re used in places where saving weight is key, like in cars and planes, and in making gadgets and electronics.

Split Rivets: For Soft Materials

Split rivets, or “drive” rivets, are for softer materials like wood or thin metal. Their design lets them grip well without harming the material. They’re great for DIY and light projects.

“Rivets are the unsung heroes of the fastening world, quietly holding everything together while providing the strength and durability that modern industries demand.”

Applications of Various Rivet Types

Rivets are used in many industries, showing their value and flexibility. They are key in making things safe, strong, and lasting. This is true for cars, planes, buildings, and gadgets.

Automotive and Aerospace Industries

In car making, rivets are used a lot. They hold body parts, chassis, and engine parts together. They also help in the aerospace world, joining planes’ parts for safety and strength.

Construction and Structural Applications

In building, structural rivets are a big deal. They help make steel frames and trusses strong. This makes sure buildings and bridges can stand up to weight and weather.

Consumer Goods and Electronics

Rivets are also used in making everyday items. They help put together laptops, phones, furniture, and appliances. This makes these products better and last longer.

“Rivets are the unsung heroes of modern manufacturing, quietly providing the strength and reliability that underpins so many of the products we use every day.”

Rivets are vital in many fields, showing their value and importance. They are used in cars, planes, buildings, and gadgets. These reliable parts are a big part of making things work well.

How to Choose the Right Rivet for Your Project

Choosing the right rivet is key for your project’s success. You need to think about material compatibility, load-bearing capacity, and what your project needs. These factors are important for your project’s performance and safety.

Factors to Consider

To pick the best rivet, look at these important factors:

- Material Compatibility: Make sure the rivet material works well with what you’re joining. This helps avoid corrosion or other problems that could harm your project.

- Load-bearing Capacity: Figure out how much weight your project will hold. Choose a rivet that can handle it. This keeps your project strong.

- Application Needs: Think about what your project needs. Consider how easy it is to see, how it will be used, and the environment. This helps you pick the right rivet size and finish.

By looking at these factors, you can pick the best rivet for your project. This ensures your project works well and lasts long.

“Choosing the right rivet is crucial for the success of any project. It’s not just about strength, but also compatibility and suitability for the specific application.”

– Jane Doe, Manufacturing Engineer

Remember, the right rivet makes a big difference in your project’s quality and life. Take your time to think about the material, load, and needs of your project. This way, you’ll get great results.

Shixinproto’s Custom Riveting Solutions

At Shixinproto, we’re proud of our custom riveting solutions. Our team works closely with clients to meet their needs. We deliver fastening solutions that go beyond what they expect.

Expertise in Providing the Best Riveting Solutions for Your Needs

With years of experience, Shixinproto is known for its craftsmanship and innovation. We use our knowledge of materials and processes to create custom riveting solutions. These solutions improve performance, durability, and cost-efficiency.

Our solutions are for various industries like automotive, aerospace, construction, and consumer goods. Shixinproto’s custom riveting meets your specific needs. Our team handles everything from material selection to quality control, ensuring top-notch products.