In today’s fast-paced manufacturing world, precision, efficiency, and quality are key. Jigs and fixtures are the unsung heroes that make it all happen. They are crucial in many industries, from cars and planes to medical devices and gadgets we all use.

Explore the world of manufacturing precision. Here, jigs and fixtures are the difference between a perfect product and a big mistake. Learn how these engineering wonders are changing how we make things, making them better and faster.

What Are Jigs and Fixtures?

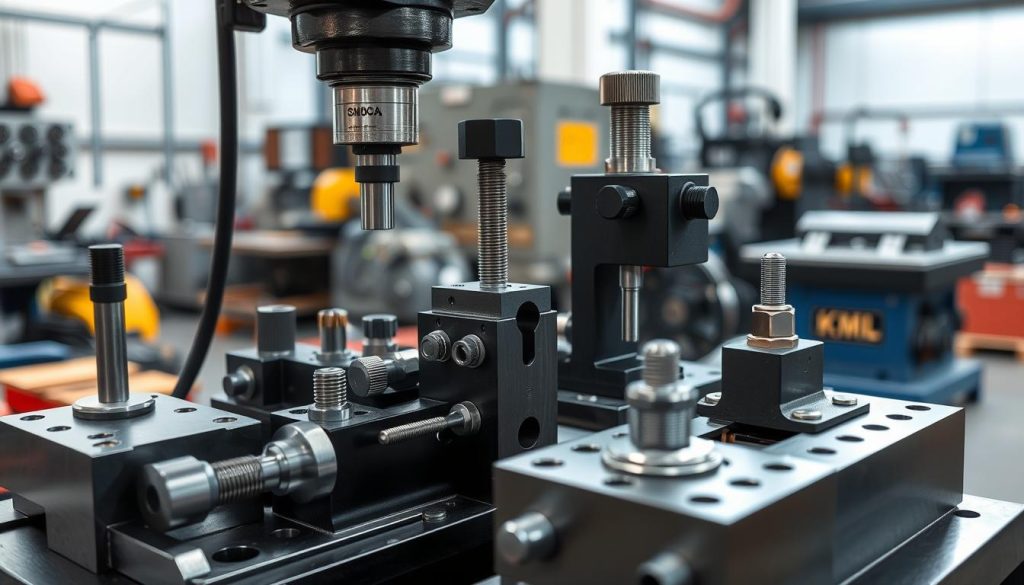

In manufacturing, jigs and fixtures are key for precise workpiece positioning and consistent machining. They help in efficient production tooling. These tools hold, support, and guide workpieces during processes like drilling, milling, or turning.

Definition and Purpose of Jigs

Jigs hold and guide workpieces for accurate operations like drilling, tapping, or assembling. They use locating elements, clamping mechanisms, and guides. This ensures the workpiece stays in the right position and orientation during manufacturing.

Definition and Purpose of Fixtures

Fixtures hold workpieces in place during operations like milling, turning, or welding. Unlike jigs, they focus on keeping the workpiece steady. This prevents movement or vibration during machining.

Key Differences Between Jigs and Fixtures

The main difference is in their function. Jigs guide the tool, while fixtures hold the workpiece. Jigs have complex features like bushings or templates for precise tool positioning. Fixtures focus on secure clamping and positioning of the workpiece.

“Jigs and fixtures are essential tools in manufacturing, ensuring consistent quality, increased productivity, and enhanced safety throughout the production process.”

Knowing about jigs and fixtures helps manufacturers improve their workflows. It enhances machining accuracy and boosts overall efficiency in the manufacturing world.

Benefits of Using Jigs and Fixtures

Using jigs and fixtures can greatly improve manufacturing. They help make products better, faster, and cheaper. These tools are key in many industries for better accuracy and safety.

Improved Accuracy and Repeatability

Jigs and fixtures make sure parts are placed correctly. This leads to better quality and efficiency. They help avoid mistakes and make products consistent.

Reduced Production Time and Costs

These tools make making things faster and cheaper. They automate tasks, saving time and money. This also means less waste and better quality, helping businesses save more.

Enhanced Safety and Consistency

Jigs and fixtures keep workers safe by holding parts in place. This reduces accidents and makes work safer. It also makes production more efficient and consistent.

| Benefit | Description |

|---|---|

| Improved Accuracy and Repeatability | Jigs and fixtures ensure precise positioning and alignment of workpieces, leading to high levels of accuracy and repeatability in manufacturing. |

| Reduced Production Time and Costs | The use of jigs and fixtures can significantly shorten production cycles and reduce overall manufacturing expenses. |

| Enhanced Safety and Consistency | Jigs and fixtures promote worker safety, minimize the risk of accidents, and contribute to higher productivity and quality assurance. |

“Jigs and fixtures are the unsung heroes of the manufacturing world, quietly improving efficiency, quality, and safety on the factory floor.”

Types of Jigs and Fixtures

In manufacturing, jigs and fixtures are key for precision and efficiency. They are used in many processes like drilling and tapping. These tools come in many designs to fit different needs.

Types of Jigs: Drilling, Tapping, and More

Jigs help guide workpieces during tasks like drilling and tapping. They ensure the workpiece is in the right spot. This leads to consistent results. Here are some common jigs:

- Drill Jigs: Guide drill bits for precise holes.

- Tapping Jigs: Help make internal threads.

- Welding Jigs: Hold parts in place for welding.

- Assembly Jigs: Help assemble complex parts.

Types of Fixtures: Milling, Turning, and More

Fixtures hold workpieces steady during machining. They keep the workpiece aligned for accurate shaping. Here are some common fixtures:

- Milling Fixtures: Hold workpieces for milling.

- Turning Fixtures: Secure workpieces for lathe work.

- Grinding Fixtures: Position workpieces for grinding.

- Clamping Fixtures: Use clamps to hold workpieces.

Both jigs and fixtures are vital in making high-quality parts. They help in achieving precision and efficiency in manufacturing.

Applications of Jigs and Fixtures in Manufacturing

Jigs and fixtures are key tools in many industries. They are used in automotive, aerospace, medical devices, and consumer electronics. These tools help make products with high precision and quality.

Automotive and Aerospace Industries

In the automotive and aerospace fields, jigs and fixtures are vital. They ensure parts are correctly aligned and positioned. This helps produce parts that meet high standards and performance.

Medical Device Manufacturing

The medical device industry needs great attention to detail. Jigs and fixtures are crucial here. They help make products accurately and safely, ensuring their quality and effectiveness.

Consumer Electronics and More

Jigs and fixtures are also used in consumer electronics and other industries. They help manufacturers achieve the precision and consistency needed. This meets the high standards of their markets.

In every industry, jigs and fixtures improve accuracy and reduce costs. They also make production safer and more consistent. This is key for success in today’s competitive world.

“Jigs and fixtures are essential tools that enable manufacturers to consistently produce high-quality products, regardless of the industry. They are the backbone of precision engineering and custom manufacturing solutions.”

Tips for Designing Effective Jigs and Fixtures

Making efficient jigs and fixtures is key for better manufacturing. When designing, think about design optimization. This includes durability, precision, and keeping costs down.

Material Selection for Durability and Precision

Choosing the right materials is crucial for jigs and fixtures. Look at material properties, how well they resist wear, and how they handle heat. The right materials help make production more reliable and cut down on maintenance.

Ensuring Compatibility with Machining Tools

Jigs and fixtures need to work well with the manufacturing ergonomics and tools. Think about tool clearances, how they clamp, and their size. This helps avoid downtime and boosts efficiency.

Factors for Cost-Effective Design

- Use less material but keep it strong

- Make production cheaper by using less labor and resources

- Use standard parts and designs to be more flexible

By focusing on these design points, makers can create jigs and fixtures that work great, improve productivity, and save money.

“Good jig and fixture design is the heart of efficient manufacturing. By picking the right materials, making sure they fit, and keeping costs low, makers can reach new heights of quality and productivity.”

Shixinproto’s Custom Jigs and Fixtures Solutions

At Shixinproto, we know how important high-precision jigs and fixtures are. They help make manufacturing better. Our team of skilled engineers and designers creates custom solutions for our clients in many industries.

High-Precision Jigs and Fixtures Tailored to Your Needs

Need specialized drilling jigs or detailed milling fixtures? Shixinproto can help. We work with you to solve your problems. Our goal is to improve your accuracy, consistency, and production speed.

Why Shixinproto is Your Ideal Manufacturing Partner

With years of experience and a focus on quality, Shixinproto is your best choice. Our advanced facilities and latest technologies ensure precise and reliable custom jigs and fixtures. Partnering with us can make your operations more efficient, saving you money and helping you stay ahead in the market.