In the world of engineering and manufacturing, the stiffness of metal materials plays a crucial role in ensuring the structural integrity and reliability of various components and structures. Stiffness, a fundamental property of metals, determines how these materials respond to applied forces, ultimately impacting their performance and the overall integrity of the final product.

Understanding the stiffness of metal materials is essential for designers, engineers, and manufacturers who seek to create durable, high-performance solutions across a wide range of industries. From aerospace and automotive to construction and industrial equipment, the ability to accurately measure, predict, and optimize the stiffness of metal materials is a critical factor in producing safe, reliable, and efficient products.

What is Stiffness in Metal Materials?

Stiffness is a crucial property of metal materials that describes their ability to resist deformation under applied loads. It is a measure of a material’s elastic modulus, which quantifies the relationship between stress and strain. In other words, stiffness reflects how much a material will flex or bend when subjected to a certain amount of force.

Definition and Importance of Stiffness

The stiffness of a metal material is defined as its resistance to elastic deformation. It is an essential characteristic that determines how the material will perform under various mechanical loads. A stiffer material will exhibit less material deformation compared to a more flexible one, which is crucial in many engineering applications where maintaining structural integrity is paramount.

How Stiffness Affects Material Performance

The stiffness of a metal material has a direct impact on its mechanical properties and overall performance. Stiffer metals tend to be more resistant to bending, twisting, and other forms of deformation, making them suitable for applications that require high load-bearing capacity, such as construction, automotive, and aerospace industries. On the other hand, less stiff metals may be more suitable for applications where some flexibility is desired, such as in the production of springs or shock absorbers.

Understanding the stiffness of metal materials is crucial in engineering design, as it helps engineers select the most appropriate materials for a given application and ensures the structural integrity and reliability of the final product.

How to Measure the Stiffness of Metal Materials

Determining the stiffness of metal materials is crucial for understanding their performance and suitability for various applications. Two key approaches are used to measure the stiffness of metals: Young’s modulus and different testing methods.

Young’s Modulus and Its Role in Stiffness Measurement

Young’s modulus, also known as the modulus of elasticity, is a fundamental property that quantifies a material’s stiffness. It represents the ratio of the stress applied to a material to the resulting strain. A higher Young’s modulus indicates a stiffer material that is more resistant to deformation under load.

Young’s modulus is determined through tensile testing, where a metal sample is subjected to a controlled stress-strain relationship. The resulting stress-strain curve provides valuable insights into the material’s stress-strain relationship and overall material characterization.

Different Testing Methods for Stiffness

In addition to tensile testing, other testing methods can be used to measure the stiffness of metal materials:

- Dynamic Mechanical Analysis (DMA): This technique applies a small, controlled oscillatory force to a sample and measures the material’s response, providing insights into its stiffness and damping properties.

- Bending Tests: These tests measure a material’s resistance to bending, which is directly related to its stiffness. Common bending tests include three-point and four-point bending.

- Compression Tests: By applying compressive forces to a metal sample, these tests evaluate the material’s resistance to deformation and its overall stiffness.

The choice of testing method depends on the specific requirements of the application and the information needed about the metal’s stiffness characteristics.

“Understanding the stiffness of metal materials is crucial for designing and selecting the right materials for various engineering applications.”

Factors Affecting the Stiffness of Metal Materials

The stiffness of metal materials is influenced by a variety of factors, including their chemical composition, processing techniques, and environmental conditions. Understanding these key factors is crucial for selecting the right metal alloy for specific applications.

The Role of Material Composition

The alloying elements present in a metal can significantly impact its stiffness. Certain elements, such as carbon, chromium, and nickel, can increase the metal’s strength and rigidity when added in the appropriate proportions. Conversely, other elements like aluminum or copper may decrease stiffness. Careful control of the material’s microstructure through precise alloying is essential for achieving the desired stiffness properties.

Impact of Temperature and Environmental Conditions

The stiffness of metal materials can be influenced by temperature and environmental factors. Exposure to high temperatures, for instance, can cause softening and a reduction in stiffness, as the heat treatment process alters the material’s internal structure. Additionally, factors like humidity, exposure to corrosive agents, and mechanical loading can all affect the metal’s stiffness over time.

The Effect of Material Processing on Stiffness

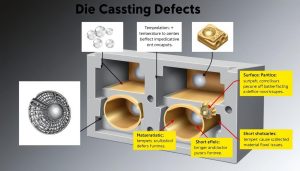

The way a metal is processed, such as through forging, casting, or rolling, can have a profound impact on its stiffness. These manufacturing techniques can modify the material’s microstructure and introduce residual stresses, which in turn influence the overall stiffness of the final product. Understanding the relationship between processing methods and stiffness is crucial for optimizing the performance of metal components.

| Factor | Effect on Stiffness |

|---|---|

| Alloying Elements | Increased stiffness with elements like carbon, chromium, and nickel |

| Temperature and Environmental Conditions | Decreased stiffness at high temperatures and in corrosive environments |

| Material Processing | Modification of microstructure and residual stresses can impact stiffness |

Stiffness vs. Strength vs. Hardness in Metals

When it comes to metal materials, understanding the key differences between stiffness, strength, and hardness is crucial for proper material selection and application. These three properties are often confused, yet they have distinct implications for the mechanical behavior of metals.

Key Differences Between Stiffness and Strength

Stiffness, measured by Young’s modulus, refers to a material’s resistance to elastic deformation under stress. It determines how much a material will bend or stretch before it reaches its yield point. Strength, on the other hand, is a measure of a material’s ability to withstand applied forces without permanent deformation or failure.

In other words, stiffness is a measure of a material’s resistance to elastic deformation, while strength is a measure of its resistance to plastic deformation or fracture. A material can be highly stiff but not necessarily very strong, or vice versa, depending on its atomic structure and the way it’s been processed.

How Hardness Relates to Stiffness in Metal Materials

Hardness is a measure of a material’s resistance to indentation or scratching. While hardness and stiffness are related, they are not the same. Hardness is influenced by a material’s atomic structure, but it does not directly determine a material’s stiffness or strength.

Highly stiff materials, such as tungsten and titanium, tend to be harder than more flexible metals like aluminum or copper. However, hardness alone does not guarantee high stiffness or strength. The material selection process must consider all three properties – stiffness, strength, and hardness – to ensure the best fit for a specific application and its mechanical behavior requirements.

| Property | Description | Relationship |

|---|---|---|

| Stiffness | Resistance to elastic deformation | Highly stiff materials tend to be harder, but hardness does not directly determine stiffness. |

| Strength | Resistance to plastic deformation or fracture | Strength and stiffness are related but not the same. A material can be highly stiff but not necessarily very strong. |

| Hardness | Resistance to indentation or scratching | Hardness is influenced by a material’s atomic structure, but it does not directly determine stiffness or strength. |

Applications of Stiff Metal Materials

The exceptional stiffness of certain metal materials has made them indispensable in a wide range of industries, from aerospace engineering to automotive manufacturing and structural design. These high-performance metals are prized for their ability to withstand heavy loads, maintain shape, and provide unparalleled strength-to-weight ratios.

Use of Stiff Metals in Engineering and Manufacturing

In the aerospace industry, stiff metals like titanium and aluminum alloys are extensively used in the construction of aircraft frames, wings, and engine components. Their remarkable rigidity and low weight are critical for ensuring the structural integrity and fuel efficiency of modern airplanes. Similarly, in the automotive sector, automakers rely on stiff metals like high-strength steel to enhance the safety and handling characteristics of vehicles.

Industries That Rely on High Stiffness Metals

Beyond aerospace and automotive, the construction industry also benefits greatly from the use of stiff metal materials. Structural steel, for instance, is a staple in the design and erection of high-rise buildings, bridges, and other large-scale infrastructure projects. Its exceptional load-bearing capacity and resistance to deformation make it an indispensable component of modern architectural and engineering feats.

| Industry | Applications of Stiff Metals |

|---|---|

| Aerospace | Aircraft frames, wings, engine components |

| Automotive | Vehicle frames, body panels, suspension components |

| Construction | Structural steel for buildings, bridges, and infrastructure |

As the demand for high-performance, lightweight, and durable materials continues to grow, the applications of stiff metal materials are poised to expand even further, driving innovation in fields like aerospace materials, automotive engineering, and structural design.

Shixinproto: Your Expert in Metal Material Selection and Fabrication

At Shixinproto, we pride ourselves on being the leading experts in custom metal fabrication and material selection. With years of experience and a deep understanding of metal materials, our team is dedicated to providing tailored engineering solutions for a wide range of industries.

Whether you’re in need of high-stiffness metals for critical applications or seeking innovative fabrication techniques, Shixinproto has the expertise to deliver exceptional results. Our commitment to quality and continuous improvement ensures that every project we undertake meets the highest standards of performance and reliability.

From aerospace to automotive, construction to consumer goods, our expertise spans a diverse range of sectors. We work closely with our clients to understand their unique requirements and deliver custom metal fabrication services that exceed their expectations. With a focus on cutting-edge technology and a passion for problem-solving, Shixinproto is your trusted partner in metal material selection and fabrication.