In the world of metalworking, tack welding has emerged as a versatile and indispensable technique. This temporary welding method plays a crucial role in ensuring precise alignment and structural integrity throughout various fabrication and construction processes. From sheet metal welding to structural fabrication, tack welding serves as a vital tool for professionals, enabling them to achieve their projects with increased efficiency and accuracy.

What is Tack Welding?

Tack welding is a fundamental technique in the world of welding, serving as a crucial step in the overall welding process. This method involves creating small, intermittent welds to temporarily hold metal parts in place before the final, continuous welding takes place. Understanding the tack welding definition and how it works is essential for any welder or fabricator.

Definition and Overview of Tack Welding

Tack welding is a welding technique that uses short, localized welds to temporarily join two or more metal pieces together. These tack welds are typically small in size and are meant to hold the parts in their desired position until the final, full-strength welds can be completed. This process helps ensure proper alignment and prevents distortion during the welding process.

How Tack Welding Works: The Process and Tools

The tack welding process involves several key steps. First, the metal parts are carefully positioned and clamped in place using specialized welding tools, such as clamps and fixtures. Then, the welder uses a welding gun or torch to create small, intermittent welds at strategic points along the joint. These tack welds are usually just a few seconds long and are spaced out to allow for easier final welding. The essential welding tools required for tack welding include a welding gun, clamps, and appropriate personal protective equipment (PPE) for safety.

| Tack Welding Tools | Description |

|---|---|

| Welding Gun | A specialized tool used to create the tack welds, typically powered by an electric or gas-powered welding machine. |

| Clamps | Devices used to securely hold the metal parts in place during the tack welding process, ensuring proper alignment. |

| Personal Protective Equipment (PPE) | Essential safety gear, including a welding mask, gloves, and protective clothing, to protect the welder during the process. |

The Purpose of Tack Welding

Tack welding serves two primary purposes in welding projects: temporarily positioning metal parts and preventing distortion during the final welding process. By strategically applying small tack welds, welders can efficiently align and secure components prior to completing the full, continuous weld.

Temporary Positioning of Metal Parts

One of the key purposes of tack welding is to hold metal parts in their desired position while the final welding is performed. This is particularly important when working with large, heavy, or complex assemblies where maintaining precise alignment can be challenging. Tack welds provide the necessary stability to keep the parts in place, making it easier to execute the final welds with accuracy and consistency.

Preventing Distortion and Ensuring Alignment

In addition to positioning the metal parts, tack welding plays a crucial role in preventing distortion during the welding process. The heat generated by welding can cause the metal to expand and potentially warp or bend. Strategically placed tack welds help to counteract these distortion forces, ensuring that the components remain properly aligned throughout the welding sequence. This results in a final weld with superior structural integrity and a consistent, uniform appearance.

By understanding the purpose of tack welding, metal positioning, and welding alignment, welders can optimize their processes, improve the quality of their work, and ultimately deliver better outcomes for their clients.

Key Benefits of Tack Welding

Tack welding is a versatile technique that offers numerous advantages in various welding projects. From faster setup for final welding to improved accuracy and cost reduction, this process delivers tangible benefits that can significantly enhance the efficiency and quality of your work.

Faster Setup for Final Welding

One of the primary advantages of tack welding is its ability to expedite the setup process for final welding. By temporarily securing the metal parts in their desired position, tack welding eliminates the need for extensive clamping and fixturing, allowing you to move on to the final welding stage more quickly. This streamlined approach not only saves time but also enhances productivity, enabling you to complete projects at a faster pace.

Improved Accuracy in Welding Projects

Tack welding plays a crucial role in ensuring the accuracy and alignment of your welding projects. The temporary bonds created by tack welds hold the metal parts in their proper position, preventing distortion and ensuring that the final weld is executed precisely as intended. This enhanced accuracy translates to a higher-quality final product, reducing the need for rework and improving the overall integrity of your work.

Reducing Material Waste and Costs

By optimizing the welding process through tack welding, you can significantly reduce material waste and associated costs. The improved accuracy and alignment achieved through tack welding minimize the likelihood of errors or misalignments that would otherwise result in the scrapping of valuable materials. This cost-saving benefit is particularly meaningful in industries where material expenses can significantly impact the bottom line, such as automotive and aerospace manufacturing.

| Tack Welding Benefits | Advantages |

|---|---|

| Faster Setup for Final Welding | – Eliminates the need for extensive clamping and fixturing – Increases productivity and saves time |

| Improved Accuracy in Welding Projects | – Prevents distortion and ensures proper alignment – Enhances the quality of the final product |

| Reducing Material Waste and Costs | – Minimizes the likelihood of errors and scrapping of materials – Significant cost savings, especially in industries with high material expenses |

With its ability to streamline the welding process, enhance precision, and drive down material costs, tack welding emerges as a highly valuable technique for a wide range of industries and applications. By leveraging the benefits of tack welding, you can unlock greater efficiency, quality, and cost-effectiveness in your welding projects.

Common Applications of Tack Welding

Tack welding is a versatile technique with a wide range of applications across various industries. From sheet metal fabrication to structural welding and automotive manufacturing, this essential process plays a crucial role in ensuring accurate, secure, and cost-effective assemblies.

Use in Sheet Metal Welding

In the realm of sheet metal welding, tack welding is indispensable. It helps align and temporarily secure metal components before final welding, preventing distortion and maintaining proper fit. This is particularly important in the fabrication of HVAC systems, ductwork, and other sheet metal products where dimensional accuracy is paramount.

Role in Structural Welding and Fabrication

Tack welding is a vital technique in structural welding and fabrication. It is used to assemble and align large, heavy-duty components, such as those found in construction, bridges, and industrial equipment. By tack welding these parts in place, welders can ensure precise positioning and minimize the risk of warping or misalignment during the final welding process.

Tack Welding in Automotive and Aerospace Industries

The automotive and aerospace industries heavily rely on tack welding to produce high-quality, durable products. In vehicle manufacturing, tack welding is used to temporarily hold body panels, structural members, and other components in place before final welding. Similarly, in aerospace applications, tack welding is critical for assembling airframe components, ensuring strength and reliability.

| Industry | Tack Welding Applications |

|---|---|

| Sheet Metal Fabrication | HVAC systems, ductwork, and other sheet metal products |

| Structural Welding and Fabrication | Construction, bridges, and industrial equipment |

| Automotive | Body panels, structural members, and other vehicle components |

| Aerospace | Airframe assembly and components |

Tack welding’s versatility and importance in these diverse industries underscore its essential role in modern manufacturing and construction processes. By leveraging the benefits of tack welding, businesses can achieve greater efficiency, accuracy, and cost-effectiveness in their welding projects.

Best Practices for Tack Welding

As a crucial step in many welding projects, tack welding requires a delicate touch. Mastering the ideal settings and avoiding common mistakes can mean the difference between a successful weld and a costly do-over. Whether you’re a seasoned pro or a novice welder, understanding the best practices for tack welding can elevate your skills and streamline your workflow.

Ideal Settings for Tack Welds

The key to creating effective tack welds lies in finding the right balance of amperage, voltage, and weld duration. Generally, lower amperage settings (around 50-100 amps) and shorter weld times (1-3 seconds) work best for tack welding, as they help minimize distortion and maintain the precise positioning of your metal components. Experimenting with different settings on scrap material can help you determine the optimal configuration for your specific project.

Common Mistakes to Avoid in Tack Welding

- Excessive weld size: Oversized tack welds can lead to warping and distortion, so aim for small, evenly spaced tacks.

- Inadequate tack placement: Poorly positioned tacks may fail to hold parts in place, compromising the final weld.

- Insufficient tack penetration: If the tack weld doesn’t fully penetrate the metal, it can lead to weak joints and potential failure.

- Rushing the process: Taking the time to set up properly and apply tack welds with care is crucial for achieving the best results.

By mastering the tack weld settings and avoiding common welding mistakes, you’ll be well on your way to producing high-quality tack welds that set the stage for flawless final welds. With these best practices in mind, your tack welding projects are sure to reach new heights of precision and success.

Shixinproto: Your Trusted Partner for Welding Services

When it comes to reliable and professional welding services, Shixinproto stands out as a trusted industry leader. With years of expertise and a commitment to excellence, the company has established itself as the go-to provider for businesses across various sectors, including construction, manufacturing, and automotive.

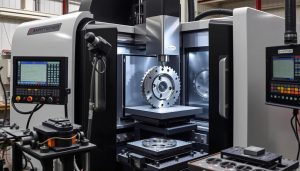

At Shixinproto, our team of skilled welding experts utilizes state-of-the-art equipment and techniques to deliver exceptional results. Whether you require precise tack welding for temporary positioning or comprehensive welding solutions for complex fabrication projects, we have the knowledge and resources to meet your needs.

Shixinproto’s unwavering focus on quality and safety ensures that your projects are completed with the utmost care and attention to detail. Our robust quality control measures and stringent safety protocols guarantee that your welding requirements are met with the highest standards, safeguarding both your project and your team.