In the ever-evolving world of technology, the demand for durable and visually appealing tablet PC casings has never been higher. Introducing the revolutionary titanium casing solutions, meticulously crafted through the precision of CNC machining. These custom-made enclosures not only protect your tablet PC but also elevate its aesthetic appeal, making it a true statement piece in the digital age.

Crafted from the strong and lightweight titanium alloy, these tablet PC casings offer unparalleled durability and corrosion resistance, ensuring your device stays protected from the rigors of daily use. The CNC machining process allows for unrivaled precision, enabling the creation of intricate designs and perfect fits that seamlessly integrate with your tablet PC.

Key Takeaways

- Titanium casing for enhanced durability and protection of tablet PCs

- Precise CNC machining for custom-made, tailored enclosures

- Lightweight and corrosion-resistant titanium alloy construction

- Elevated aesthetic appeal and design flexibility

- Optimal solution for tablet PC users seeking premium protection and style

Benefits of Titanium Casing for Tablets

When it comes to protecting your tablet PC, the choice of casing material can make all the difference. One material that has gained popularity for its exceptional durability and performance is titanium. Titanium offers a range of benefits that make it an ideal choice for tablet protection.

Durability and Strength of Titanium

Titanium is renowned for its exceptional strength-to-weight ratio, which means it can provide robust protection for your tablet without adding excessive bulk or weight. This material is highly resistant to dents, scratches, and impacts, ensuring your tablet remains in pristine condition even when faced with daily wear and tear.

Lightweight and Corrosion Resistance

In addition to its impressive strength, titanium is also remarkably lightweight. This makes it an ideal choice for tablet casings, as it won’t weigh down your device or compromise its portability. Furthermore, titanium is highly corrosion-resistant, making it a long-lasting and durable option for your tablet’s corrosion-resistant casing.

Aesthetic and Design Flexibility

Beyond its practical benefits, titanium also offers a sleek and modern aesthetic that can elevate the appearance of your tablet. This material can be machined and finished in a variety of ways, allowing for a wide range of design flexibility to suit your personal style preferences. Whether you prefer a minimalist or bold look, titanium can be crafted to meet your needs.

By choosing a titanium benefits casing for your tablet, you can enjoy the ultimate in tablet protection, combining durability, lightweight construction, and aesthetic appeal. Unleash the full potential of your tablet with the exceptional performance of a titanium casing.

| Benefit | Description |

|---|---|

| Durability and Strength | Titanium’s exceptional strength-to-weight ratio provides robust protection against dents, scratches, and impacts, keeping your tablet safe. |

| Lightweight and Corrosion Resistance | Lightweight yet highly corrosion-resistant, titanium casings don’t weigh down your device and offer long-lasting protection. |

| Aesthetic and Design Flexibility | Titanium can be machined and finished in various ways, allowing for a wide range of design flexibility to suit your personal style preferences. |

CNC Machining Techniques for Titanium

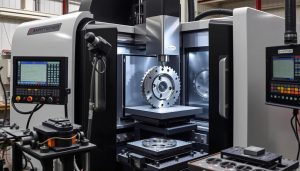

Crafting exceptional titanium casings for tablet PCs requires a meticulous approach to CNC machining. This specialized process combines precision cutting and shaping techniques with advanced surface finishing methods to achieve the desired level of quality and performance.

Precision Cutting and Shaping

The CNC machining of titanium involves intricate cutting and shaping operations to create the precise contours and dimensions required for a tablet’s casing. Utilizing state-of-the-art CNC machines, skilled technicians carefully program the cutting paths and tool movements to ensure a high degree of accuracy and repeatability. This attention to detail is crucial in producing the seamless, uniform appearance that consumers expect from premium tablet devices.

Surface Finishing and Polishing

Once the titanium casing has been precisely cut and shaped, the next step is to refine the surface finish. Various techniques, such as CNC milling, turning, and grinding, are employed to achieve the desired texture and level of smoothness. Additionally, advanced polishing methods are used to impart a lustrous, premium look to the titanium components. This meticulous attention to surface finishing ensures that the tablet’s casing not only feels exceptionally durable but also exudes a high-end, sophisticated aesthetic.

“The key to successful CNC machining of titanium is the perfect balance of cutting-edge technology and skilled craftsmanship.”

By mastering these specialized CNC machining techniques, manufacturers can consistently deliver titanium casings that not only protect the tablet but also enhance the overall user experience through their exceptional durability, lightweight, and refined appearance.

Choosing the Right Titanium Material for CNC Machining

When it comes to CNC machining for tablet casings, the selection of the right titanium material is crucial. Titanium grades offer distinct properties and characteristics, each with its own advantages. Let’s explore two popular titanium options: Grade 5 Titanium (Ti-6Al-4V) and Grade 2 Titanium.

Grade 5 Titanium (Ti-6Al-4V)

Grade 5 Titanium, also known as Ti-6Al-4V, is a widely used alloy in the aerospace and medical industries due to its exceptional strength and durability. This titanium grade is an excellent choice for tablet casings that require high mechanical performance and resistance to wear and tear. With a tensile strength nearly twice that of stainless steel, Ti-6Al-4V offers exceptional protection for your device.

Grade 2 Titanium for Lightweight Applications

For tablet designs prioritizing lightweight characteristics, Grade 2 Titanium is an ideal material. This pure titanium grade is less dense than Grade 5, making it a preferred choice for applications where weight reduction is a key consideration. Grade 2 Titanium delivers a balanced combination of strength and corrosion resistance, making it a reliable option for lightweight tablet casings.

| Property | Grade 5 Titanium (Ti-6Al-4V) | Grade 2 Titanium |

|---|---|---|

| Tensile Strength | 900-1,000 MPa | 480-550 MPa |

| Density | 4.43 g/cm³ | 4.51 g/cm³ |

| Corrosion Resistance | Excellent | Excellent |

| Suitable Applications | High-performance tablet casings | Lightweight tablet casings |

When selecting the right titanium grade for your tablet CNC machining needs, carefully consider the desired performance characteristics, such as strength, weight, and corrosion resistance. By choosing the appropriate titanium material, you can ensure your tablet casings deliver the optimal balance of durability, aesthetics, and functionality.

Key Considerations for CNC Machining Titanium

Crafting the perfect titanium casing for tablet PCs requires a deep understanding of the unique challenges associated with CNC machining this resilient alloy. From selecting the right cutting tools to managing heat during the process, each step plays a crucial role in achieving the desired surface finish and part integrity.

Tooling Requirements and Cutting Speeds

Titanium’s inherent hardness and low thermal conductivity demand specialized cutting tools designed to withstand the rigors of machining. Carbide and ceramic tools, with their exceptional wear resistance, are typically the go-to choice for titanium machining. Maintaining optimal cutting speeds is equally important, as excessive speeds can generate excessive heat and lead to premature tool wear or even breakage.

Heat Management During Machining

Effective heat management is paramount when CNC machining titanium. The material’s low thermal conductivity can cause rapid localized heating, leading to dimensional inaccuracies, surface defects, and potential damage to the cutting tools. Utilizing a robust coolant system, along with strategic tool path planning, is essential to dissipate heat and maintain tight tolerances.

Surface Finish Quality and Its Importance

Achieving a high-quality surface finish is not just an aesthetic consideration for tablet PC casings; it also plays a crucial role in functional performance. Smooth surfaces reduce the risk of stress concentrations, improve corrosion resistance, and enhance the overall user experience. Careful attention to cutting parameters, tool selection, and post-processing techniques, such as polishing, is required to deliver the desired surface finish.

By addressing these key considerations, CNC machining professionals can unlock the full potential of titanium, delivering tablet PC casings that combine exceptional durability, lightweight, and striking visual appeal.

“Mastering the art of CNC machining titanium is a game-changer in the world of tablet PC design and engineering.”

Why Choose Shixinproto for CNC Titanium Casing Solutions?

When it comes to custom tablet enclosures, Shixinproto stands out as a leading manufacturer renowned for its expertise in CNC machining of titanium casings. With a proven track record of delivering high-performance, durable, and aesthetically-pleasing solutions, Shixinproto is the go-to choice for businesses seeking exceptional titanium casing solutions.

Shixinproto’s team of skilled engineers and technicians utilize the latest CNC machining technologies to ensure precise cutting, shaping, and surface finishing of titanium components. Their unwavering commitment to quality is reflected in the meticulous attention to detail that goes into every project, from material selection to final product inspection.

As a trusted Shixinproto, you can expect a seamless collaboration process, where your unique requirements are meticulously understood and translated into custom titanium enclosures that not only meet but exceed your expectations. With a focus on innovation and continuous improvement, Shixinproto is poised to be your reliable partner in the world of CNC-machined titanium casing solutions for tablet PCs.