In the world of manufacturing, a machine shop plays a crucial role in the production of precision parts and components. These specialized facilities are where the magic happens – where raw materials are transformed into intricate, high-quality products that power industries across the globe.

A machine shop is a workshop or facility equipped with various types of machines, tools, and equipment used for the fabrication, repair, and maintenance of mechanical parts and components. These shops are at the heart of the manufacturing process, serving as the hub where the design, engineering, and production of custom-made parts come together seamlessly.

Whether you’re an automotive enthusiast, an aerospace engineer, or a medical device manufacturer, chances are the parts and components you rely on were created in a state-of-the-art machine shop. From the smallest precision screws to the largest industrial machinery, these facilities are the backbone of modern manufacturing, ensuring that the products we use every day are built to the highest standards of quality and performance.

What is a Machine Shop?

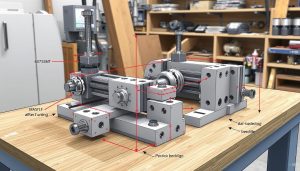

A machine shop is a specialized facility dedicated to the production, fabrication, and modification of various parts, components, and equipment. At the heart of a machine shop lies a collection of high-precision tools and machinery, enabling skilled technicians to transform raw materials into finished products with exceptional accuracy and efficiency.

Definition and Overview of a Machine Shop

The term “machine shop” refers to a workshop or industrial setting where machinists, engineers, and technicians use a variety of tools and machines to shape, cut, grind, and assemble metal and other materials into desired forms. This process, known as “machining,” involves the removal of material from a workpiece to create the desired shape, size, and finish.

Types of Machine Shops: Small vs Large Facilities

Machine shops can vary in size and scope, ranging from small, specialized facilities to large-scale industrial operations. Small machine shops typically focus on custom fabrication, prototyping, and small-batch production, catering to the needs of individual clients or small businesses. In contrast, large machine shops often serve the manufacturing demands of major industries, such as aerospace, automotive, and heavy machinery, with the capability to handle high-volume production and complex machining processes.

| Characteristic | Small Machine Shops | Large Machine Shops |

|---|---|---|

| Clientele | Individual clients, small businesses | Major industries (aerospace, automotive, heavy machinery) |

| Production Capacity | Custom fabrication, prototyping, small-batch production | High-volume production, complex machining processes |

| Equipment | Specialized, high-precision tools and machines | Large-scale, advanced manufacturing equipment |

“A machine shop is a place where the art of manufacturing is practiced with the aid of various machine tools and the skill of the machinists.”

Regardless of their size, all machine shops share a common purpose: to transform raw materials into functional, high-quality components and products that meet the specific needs of their clients.

The Machining Process in a Machine Shop

At the heart of every machine shop lies a dynamic and intricate machining process. This process, often referred to as subtractive manufacturing, involves the systematic removal of material from a workpiece to create the desired shape and precision. Machine shops leverage an array of specialized tools and equipment to execute this meticulous process, transforming raw materials into functional components.

Tools and Equipment Used in Machine Shops

Machine shops are equipped with a diverse range of tools and equipment to facilitate the machining process. Some of the most common include:

- Lathes for turning operations

- Milling machines for milling operations

- Drill presses for drilling operations

- Grinders for surface finishing

- CNC (Computer Numerical Control) machines for automated precision

The Subtractive Manufacturing Process Explained

Subtractive manufacturing, the foundation of the machining process, involves selectively removing material from a workpiece to create the desired shape and features. This process requires skilled operators to carefully control the depth, speed, and feed rate of the cutting tools to ensure the final product meets the specified tolerances and quality standards.

Common Machining Techniques: Milling, Turning, Drilling

Machine shops employ a variety of machining techniques to meet the diverse needs of their clients. Some of the most common techniques include:

- Milling: A process that uses rotating cutting tools to remove material and create features such as slots, pockets, and complex shapes.

- Turning: A process that involves rotating a workpiece while a cutting tool is used to remove material, primarily used for cylindrical parts.

- Drilling: A process that uses a rotating drill bit to create holes of various sizes and depths in the workpiece.

These techniques, combined with the skilled use of specialized tools and equipment, allow machine shops to produce a wide range of custom parts and components with exceptional precision and efficiency.

Industries That Benefit from Machine Shops

Machine shops play a vital role in supporting a wide range of industries, from automotive and aerospace to medical device manufacturing. These versatile facilities are the backbone of many manufacturing processes, providing essential custom parts, precision machining, and innovative solutions to meet the evolving needs of diverse sectors.

Automotive and Aerospace Industries

The automotive and aerospace industries rely heavily on machine shops to produce high-quality components and parts. From engine blocks and transmission gears to aircraft fuselage panels and landing gear, machine shops are instrumental in the manufacturing of these complex and critical automotive and aerospace parts. Their expertise in machine shop industries and specialized machining techniques ensures the precision and reliability required in these fast-paced, high-performance industries.

Manufacturing of Medical Devices and Electronics

The medical device and electronics manufacturing industries also benefit greatly from the services of machine shops. These facilities are adept at producing intricate, miniaturized components for medical devices, as well as precision-engineered parts for electronic products. Their ability to work with a wide range of materials, from metal to plastics, makes them invaluable partners in the medical device manufacturing and electronics industries.

Construction and Heavy Machinery Applications

The construction and heavy machinery sectors often turn to machine shops for the manufacture of specialized parts and components. From construction equipment like excavators and cranes to industrial machinery used in mining and energy production, machine shops are instrumental in ensuring the reliability and performance of these critical assets. Their expertise in automotive machining and aerospace parts production translates well to the demands of the construction and heavy machinery industries.

“Machine shops are the unsung heroes of modern manufacturing, providing the essential components and solutions that power some of the world’s most vital industries.”

What Services Can You Expect from a Machine Shop?

When it comes to manufacturing and product development, a reliable machine shop is an invaluable resource. These specialized facilities offer a wide range of services that can streamline your production process and bring your ideas to life. Let’s explore the key services you can expect from a top-notch machine shop.

Custom Part Fabrication and Precision Machining

One of the primary services offered by a machine shop is the ability to fabricate custom parts and components with exceptional precision. Using advanced machinery and skilled technicians, they can create highly accurate parts tailored to your specific requirements. Whether you need a single prototype or a batch of production-ready parts, a machine shop can handle custom part fabrication and precision machining with ease.

Prototyping and Product Development

Bringing a new product to market often requires the creation of prototypes to test and refine the design. Machine shops are well-equipped to handle the prototyping process, allowing you to iterate and perfect your product before committing to full-scale production. Their expertise in product development can also prove invaluable in transforming your concept into a tangible, functional reality.

Maintenance and Repair of Equipment and Components

In addition to fabrication and prototyping, many machine shops offer maintenance and repair services for a wide range of equipment and components. This can be particularly beneficial for industries that rely on specialized machinery, such as automotive, aerospace, and manufacturing. By partnering with a trusted machine shop, you can ensure your critical assets remain in top condition and minimize costly downtime.

When you choose a reputable machine shop, you can expect a comprehensive suite of machine shop services tailored to your unique needs. From custom part fabrication and precision machining to prototyping and equipment maintenance, these facilities can be a valuable partner in your quest for manufacturing excellence.

Why Choose Shixinproto for Your Machine Shop Needs

When it comes to your machine shop requirements, Shixinproto stands out as the premier choice. With years of expertise in precision machining and custom fabrication, our team has the skills and resources to tackle even the most complex projects with unwavering dedication and quality.

At Shixinproto, we pride ourselves on our commitment to customer satisfaction. Our state-of-the-art facilities are equipped with the latest technology and machinery, ensuring that every component we produce meets the highest standards of precision and reliability. Whether you need custom parts for your automotive, aerospace, or medical device applications, you can trust Shixinproto to deliver exceptional results.

What truly sets us apart is our passion for innovation and problem-solving. Our experienced engineers work closely with clients to understand their unique needs and develop tailored solutions that exceed their expectations. From prototyping to full-scale production, Shixinproto is your one-stop-shop for all your machine shop requirements.