In the world of power generation, steam turbines play a key role. Their efficiency and performance are crucial. The precision polishing of turbine blades is a key factor in their optimal operation.

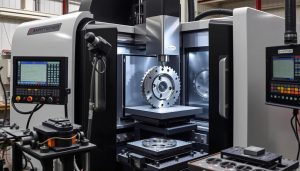

Manufacturers have adopted 5-axis CNC machines for this process. These machines offer advanced capabilities. They help achieve better surface finish quality and blade geometry accuracy.

Using 5-axis CNC technology, manufacturers can now polish steam turbine blades to new heights. This approach boosts turbine efficiency and cuts down on maintenance costs. It also extends the life of these vital components.

The impact of precision-polished turbine blades is significant. It’s felt across the industry, whether in power plants or aerospace applications.

Understanding Steam Turbine Blade Polishing

In the world of steam turbine making, the finish of turbine blades is key. It affects how well they work and how long they last. The turbine blade surface finish shows the care and precision in making them.

Importance of Precision Polishing in Turbine Blade Manufacturing

The finish of turbine blades is crucial for their efficiency and dependability. A smooth surface cuts down on air resistance, saving energy and boosting performance. Also, a precise turbine blade surface finish lowers the chance of early wear, making blades last longer and needing less upkeep.

How 5-Axis CNC Machines Contribute to Polishing Efficiency

The introduction of 5-axis CNC machines has changed how turbine blades are polished. These advanced machines offer better control and flexibility. They can polish complex blade shapes efficiently. Thanks to 5-axis CNC tech, makers can create high-quality blades consistently.

“The surface finish of turbine blades is a critical factor that significantly impacts their performance and longevity.”

Adding 5-axis CNC machines to making turbine blades has greatly improved polishing. Now, the finished blades meet the high standards of the power and aerospace sectors.

Advantages of Using 5-Axis CNC for Turbine Blade Polishing

The use of 5-axis CNC technology has changed how we polish steam turbine blades. It brings many benefits that help improve turbine performance and cut down on costs.

Improved Surface Finish and Accuracy

5-axis CNC machines offer a better surface finish and accuracy. They can control the tool path precisely. This ensures a smooth, mirror-like finish on complex blade shapes.

This precision is key for improving the blades’ aerodynamic properties. It boosts the turbine blade quality and makes the turbine run more efficiently.

Enhanced Tool Life and Reduced Operational Costs

Using 5-axis CNC machines for polishing also has big CNC machining benefits. It extends tool life and lowers operational costs. These machines work more efficiently, removing material consistently and reducing tool wear.

This leads to fewer tool replacements and less maintenance. It makes the turbine manufacturing process more efficient overall.

“The advancements in 5-axis CNC technology have enabled us to achieve a level of precision and efficiency in turbine blade polishing that was previously unattainable.”

Key Techniques in Polishing with 5-Axis CNC Machines

Using 5-axis CNC technology, makers can do amazing things with polishing steam turbine blades. They use CNC tool path optimization and the special skills of CNC machines to handle complex blade geometries smoothly.

Optimal Tool Path Strategies for Blade Polishing

One big trick in 5-axis CNC polishing is making the right tool path plans. By planning out the tool’s moves, makers can remove material evenly and get a top-notch finish on the whole blade. They think about things like tool direction, speed, and how the tool touches the blade to polish it best.

Advanced CNC Features for Polishing Complex Geometries

Turbine blades have tricky shapes that are hard to polish with old methods. But, 5-axis CNC machines with advanced polishing techniques can handle these challenges. They have tools like adaptive machining and live monitoring to control the polishing closely, making sure even the most complex blades look great.

- Adaptive machining lets the CNC machine change its path and settings as it goes, fitting the blade’s shape perfectly.

- Real-time monitoring keeps an eye on important polishing details, so makers can tweak things on the fly to keep the finish perfect.

By using these advanced methods and CNC tools, makers can always hit the high standards of the steam turbine world. This leads to better performance and efficiency.

Applications in Power Generation and Aerospace

Turbine blades need to be precise and perform well in power generation and aerospace. Power plant efficiency and aerospace applications depend on them. This is because turbine performance optimization is key.

The Role of Polished Turbine Blades in Power Plants

In power plants, the finish of turbine blades affects efficiency. Polished blades cut down on aerodynamic losses. This means better power plant efficiency and less fuel use.

This leads to lower costs and a smaller environmental impact. It’s good for both the planet and the wallet.

Aerospace Uses for High-Precision Polished Blades

The aerospace world also needs precise turbine blades, especially for jet engines. Aerospace applications need blades with a top-notch finish. This is for better airflow, less drag, and better turbine performance optimization.

Polished blades help jets use less fuel, go faster, and last longer. They’re crucial for modern aircraft.

| Application | Benefit of Polished Turbine Blades |

|---|---|

| Power Generation | Increased power plant efficiency, reduced fuel consumption |

| Aerospace | Optimized airflow, reduced drag, enhanced turbine performance |

“The surface quality of turbine blades is a critical factor in achieving optimal performance in both power generation and aerospace applications.”

Using 5-axis CNC polishing, makers can create top-notch turbine blades. These blades boost efficiency and performance across many fields.

How Shixinproto Can Support Your Steam Turbine Blade Manufacturing Needs

At Shixinproto, we’re experts in making turbine blades. We use top-notch CNC polishing to meet your custom needs with great precision and speed.

Our 5-axis CNC machines give your blades a perfect finish and accuracy. They meet the highest performance standards. We handle complex shapes with ease, thanks to our advanced tools and strategies.

Need lots of blades or something special? Shixinproto is here to help. Our skilled team works with you to create blades that boost power or serve aerospace needs. Count on Shixinproto for your blade manufacturing needs.

FAQ

What is the purpose of 5-axis CNC machine polishing for steam turbine blades?

5-axis CNC machine polishing makes steam turbine blades more efficient and last longer. It improves the blades’ surface and accuracy. This leads to better aerodynamics, lower maintenance costs, and more power generation.

How do 5-axis CNC machines contribute to the polishing efficiency of steam turbine blades?

5-axis CNC machines are more precise and flexible than old methods. They allow for detailed tool paths and efficient material removal. This results in a smooth surface finish on the entire blade.

What are the key advantages of using 5-axis CNC for turbine blade polishing?

The main benefits include a better surface finish and accuracy, longer tool life, and lower costs. 5-axis CNC polishing boosts turbine performance and longevity. It also saves on maintenance and increases efficiency and cost savings.

What specific techniques are employed in 5-axis CNC polishing of steam turbine blades?

Techniques include optimized tool paths for even material removal and surface finish. Advanced CNC features like adaptive machining and real-time monitoring help polish complex shapes. This improves the precision and quality of the blades.

How do polished turbine blades produced with 5-axis CNC technology benefit power generation and aerospace applications?

In power generation, polished blades increase efficiency and cut fuel use. In aerospace, they enhance jet engine performance and reliability. This leads to better aerodynamics and less maintenance.